Corten steel

Where does corten steel originate from?

The United States of America Steel Corporation developed corten steel in the 1930s to make coal cars for railroads and bridges, where maintenance of the underside was particularly difficult. With corten steel, there was no need to paint the steel and it was strong, weldable and weather-resistant.

Corten steel was subsequently used for several types of protection (including façade cladding) in the early 1960s. Today, corten steel is still used in architecture in many places - such as Bryggen in Vejle, the steam boiler building in Silkeborg's paper factory and Farum Midtpunkt.

How can corten steel last when it rusts?

Corten steel rusts quickly on the surface, but it has a slower corrosion rate than mild steel. Corten steel holds up well - even if it looks rusty. This is because corten steel only rusts on the surface, and the rust on the surface helps protect the steel.

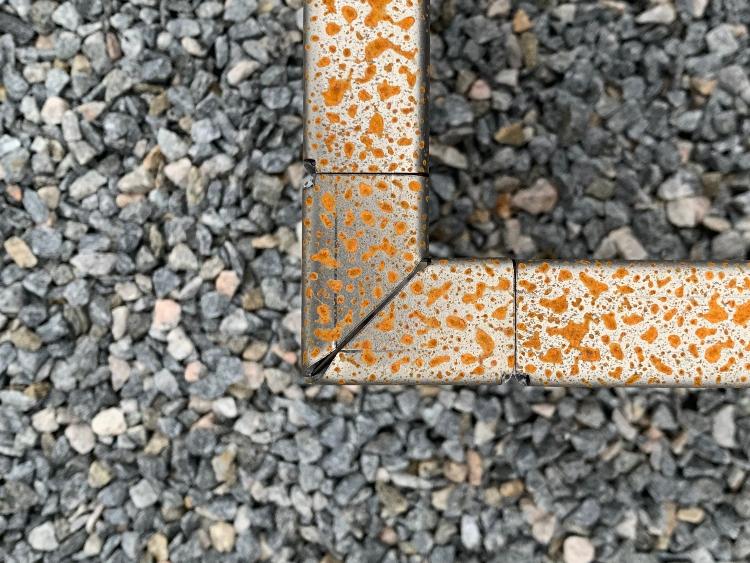

At the beginning of the rusting process, the rust may drip onto the surface and stains may appear. This can be avoided by placing some tarpaulin under the edges for the rust to drip onto. After a few months, the rusting process will slow down and there will be no more dripping.

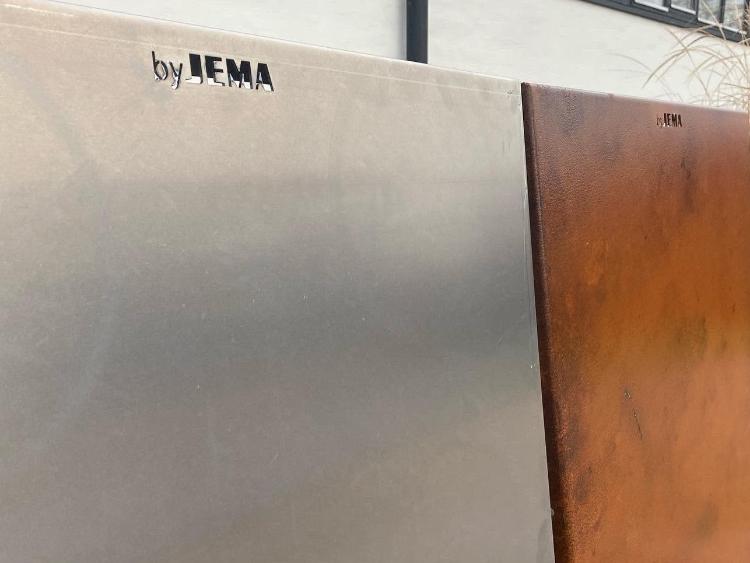

It is normal for corten steel to rust at different rates. This may be because there is still an oil layer on the plates that rust more slowly. It can help to wash the plates that have not rusted much in salt water once. When the plates get rain, the process will really pick up speed and the rusting process will accelerate.

The color of corten steel changes over time. The color will change from orange, reddish brown, brown to almost black over time.

Why does corten steel flake?

The appearance of corten steel develops over time and it is normal for it to flake a little at the bottom where there is the most water. This has no bearing on the durability of the corten steel. It's also important to note that rust is 7 times thicker than the original steel.

So 2 mm of corten steel becomes 14 mm of rust. This means that 0.3 mm of rust comes off in 2.1 mm flakes, which can make it look worse than it is. The flakes will not disappear (unless broken off) and they will protect the steel underneath. If you want to remove some of the flakes for aesthetic reasons, you can use a pan sponge or some sandpaper.